NEW PRODUCT DEVELOPMENT

Beating the competition at new product development and introduction (NPDI) is critical to a company’s success and profitability. It’s also a major challenge loaded with obstacles, targets, and trade-offs. Common best practices, like gated processes and cross-departmental teams, are designed to help New Product Development activities. A structured NPD process will help organizations to develop right product in shortest possible time.

- – Concept Development

- – Benchmarking

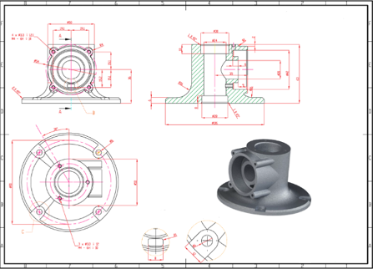

- – CAD Modelling Detailing

- – Design Specification

- – Virtual Verification

- – Simulation Driven Design

- – Design For Manufacturing DFM

- – Testing and Manufacturing Support

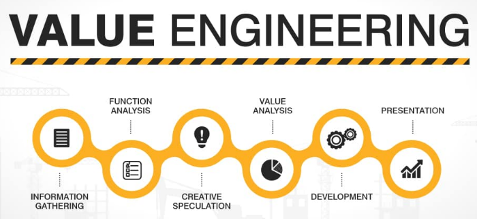

PRODUCT ENGINEERING AND OPTIMIZATION

The goal of product engineering is to optimize the cost and performance of an existing product by adding new functionalities and taking advantage of the latest technologies. It involves some of the new technologies used for developing a new product while taking advantages of the existing design and functionality.

- – Weight Reduction

- – Value Engineering

- – Cost Engineering

- – Design For Manufacturing DFM

- – Reverse Engineering

- – CAD Customization

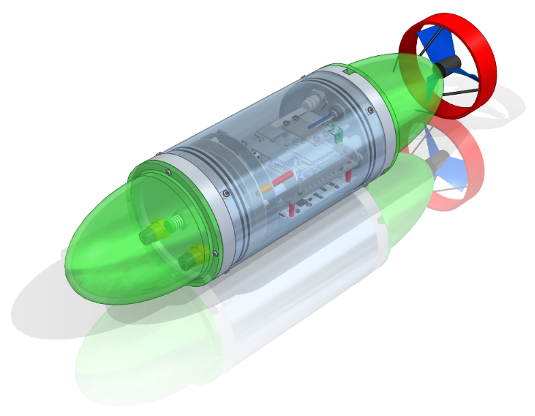

ELECTRONICS DESIGN

Electronics industry needs be quick in responding to customer needs and develop products that match OR exceed the expectations. By using the state-of-the-art SW design tools, optimized and cost effective products are developed and launched with reduced time-to-market.

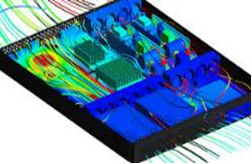

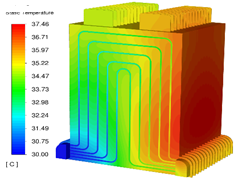

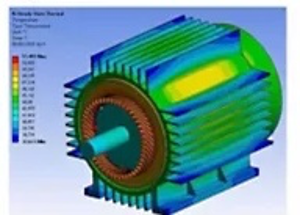

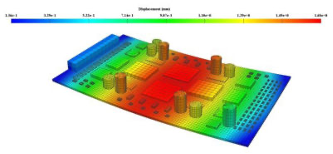

CAE SIMULATION

With ever shrinking timelines and budgets, CAE simulation is an important tool in the hands of designers and engineers. Modern CAE simulation tools help engineers run various what-if scenarios before a product is made. Our expert team of simulation engineers; can help you put together a simulation model which can accurately represent various phenomena experienced by the product. We have experience of putting together parametric simulation models with specific design goal. We work hand in hand with our customer teams to ensure that our simulation models meet strict deadline, meet quality criteria and reduce the overall development costs.

Structural and Durability Simulations (FEA)

- – Linear Static

- – Non-linear Static

- – Harmonic and Transient

- – Spectrum

- – PSD – Random Vibration

- – Durability

- – NVH

- – Drop and Impact

- – Thermal Distortio

Cooling and Thermal Simulations (CFD)

- – Incompressible and Compressible

- – Steady-state and Transient

- – Conjugate Heat transfer

- – Wind Load Calculations

- – Porous Media Analysis

- – Moving Reference Frame – MRF

- – Moving Mesh Simulation

- – Multiphase Flow Simulation

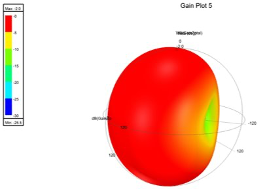

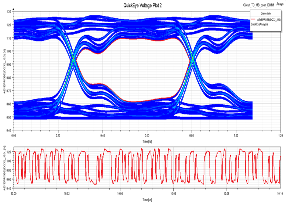

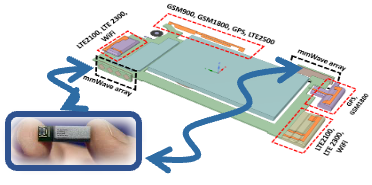

Electronics Simulation

- – Signal Integrity

- – Power Integrity

- – EMI/EMC

- – Antenna, Radome and Radars

- – Thermal Management

Electrical Simulation

- – Motor

- – Transformer

Advanced Engineering Simulations

- – Optics and Lighting Simulation

- – Multibody Dynamics (MBD)

- – Particle Simulation – Discrete Element Method (DEM)

- – 1D – Simulation