E M I / E M C

Electromagnetic compatibility (EMC) is the ability of electrical equipment and systems to function acceptably in their electromagnetic environment, by limiting the unintentional generation, propagation and reception of electromagnetic energy which may cause unwanted effects such as electromagnetic interference (EMI) or even physical damage in operational equipment.

The goal of EMC is the correct operation of different equipment in a common electromagnetic environment. It is also the name given to the associated branch of electrical engineering.

EMC pursues three main classes of issue. Emission is the generation of electromagnetic energy, whether deliberate or accidental, by some source and its release into the environment.

View Full equipment list

| Specifications | Equipment Name | |

|---|---|---|

| 1 | ESD Simulator | 1. ESD Simulator ( +-30KV) --Qty 1 2. De Humidifier --Qty 1 |

| 2 | Surge, EFT,VDI & PFMF | 1. EFT, Surge, VDI Generator (±6kV Surge, ±4kV EFT )-- Qty 1 2. EFT Calibration Kit-- Qty 1 3. Capacitive Coupling Clamp--Qty 1 4. I/O Line Coupler and Decoupler --Qty 1 5. Telecom Line Coupler/Decoupler --Qty 1 6. Magnetic Field immunity Loop -Qty 1 7. Necessary test software --Qty 1 |

| 3 | Harmonics & Flicker Analyser (6kVA) | Single phase equipment with 16A considered instead of 3 phase equipment |

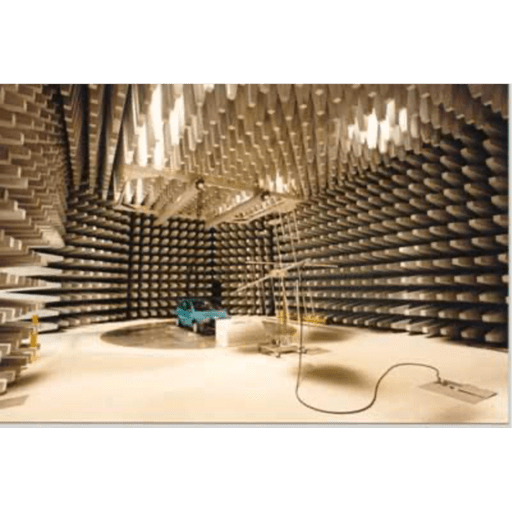

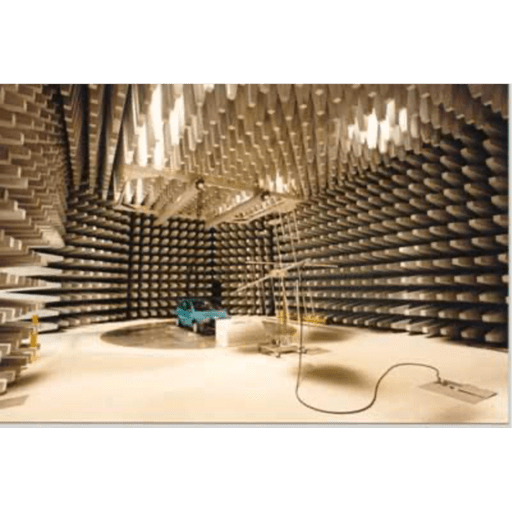

| 4 | Automotive Transient | Specifications : Test voltage 25V - 1,000V ± 10% Rise time 5ns ± 1.5 ns Verification as As per Annex C of ISO 7637-2:2011 into 50ohm and 1,000ohm load |

| 5 | Conducted Immunity, CRO and Assembly | 1. Conducted Immunity Generator -- Qty 1 2. 6 dB attenuator --Qty 1 3. Injection probe--Qty 1 4. calibration kit --Qty 1 5. 50cm BNC cable --Qty 1 6. CDN--1 set 7. EM clamp 8. Ground Reference planes --1 set 9. Test Tables--1 set 10. RF Cables and Accessories--1 set 11. Oscilloscope 12. Differential probe (± 7kV) Single phase equipment with 16A considered instead of 3 phase equipment |

| 6 | Radiated Emission and Radiated Immunity | 1. Horn Antenna (1.0GHz - 40GHz) Qty 1+1, Active monopole antenna (9KHz - 30Mhz) Qty 1, Active loop antenna (9 kHz - 30 MHz) Qty 1, Van Veen Loop Antenna Qty 1, Biconical & Log periodic antenna (26 MHz–6 GHz) Qty 1+1, Stacked Double log Periodic Antenna (0.7 - 9 GHz ) Qty 1, Double Ridged Broadband Horn (1 GHz...18 GHz) Qty 1, Rs 5,00,000 2. EMI Receiver (20 Hz to 40 GHz) Rs 90,00,000 3. RF Cables 1 set, RF Connectors 1 set, Software & Firmware Rs 25,00,000 4. Filed Monitor Qty 1, Signal Generator (9kHz-6GHz) Qty 1, Power Meter Qty 1, Signal Generator (9kHz-6GHz) Qty 1, Power Meter Qty 1, Average power sensor Qty 2, RF Power Amplifier Qty 1 set, Field probe Qty 2 Rs 5,00,00,000 |

| Conducted Emission | 1. EMI Test Receiver (9kHz - 3GHz) and Pulse Limitier ( 0-30 Mhz)Qty1 - Rs 50,00,000 2. Single Phase LISN (9kHz - 30Mhz, 16A) Qty 1-Rs 5,00,000 3. Coupling Network - Eight wire ISN-Kit Qty 1- Rs 5,00,000 4. Probe set E and H near field measurements,100 KHz – 2 GHz, Battery charger 220V and Active probe [9KHz-30KHz] and Passive Voltage Probe 9 KHz – 30 MHz Qty 1 each -Rs 5,00,000 5. RF-Current probe Qty 1 Rs 2,50,000 6. Absorbing clamp [ 30 – 1000MHz] & 50 ohm with 5 meter long RF cable both end N male connector Qty 1 each -Rs 5,00,000 Single phase equipment with 16A considered instead of 3 phase equipment |

|

| 7 | 10 meter Semi Anechoic chamber | 10 meter Semi Anechoic chamber considered till 40GHz along with Control Room, Amplifier room and one Shielded room. |

| Accessories including ground reference planes, Test Tables, Test jigs, RF cables and accessories, Software and Firmware |

1. Radiated Emission:

Purpose: To measure the electromagnetic field strength of the emissions that are unintentionally generated by your product.

Standard:

EN 55011 / CISPR 11; EN 55016 / CISPR 16; EN 55032 / CISPR 32;

Specification:

Frequency Range : 30MHz to 1 GHz

Measurement Distance : 10 Meter & 3 Meter

Antenna Polarization : Vertical & Horizontal

Antenna Height : 1 Meter to 4 Meter

Measurement Parameters : Peak, Quasi & Avg. Peak

2. Surge Voltage:

Purpose: To find shorts and insulation weaknesses in coils, windings, electric motors, generators, alternators and transformers.

Standard:

EN 61000-4-5 / IEC 61000-4-5

Specification:

Power Line up to : ± 6kV

Signal Line up to : ± 6kV

Phase angle : 0° to 360°

Power Line : Power Line CDN

Signal / Telecom Line : IO CDN / Telecom CDN

Method : Injection

3. Electrostatic Discharge:

Purpose: To evaluate the durability of electronic devices when electrostatic discharge occurs when a person touches them.

Standard:

EN 61000-4-2 / IEC 61000-4-2

Specification:

ESD Generator Parameter : ± 30kV

Support up to

Discharge Type : Contact & Air

Discharge Networks : 150pF/330Ω; 150 pF/2KΩ

330 pF/2K Ω; 330pF/330Ω

4. Conducted Emission:

Purpose: To measure the portion of electromagnetic energy created by the product that is conducted onto the power supply cord.

Standard:

EN 61000-4-2 / IEC 61000-4-2

Specification:

Frequency Range : 9KHz to 30 MHz

Measurement Method : Voltage & Current Probe

Measurement Facility : Shielded Room

Maximum Current Capacity : up to 200A

Measurement Parameters : Peak, Quasi & Avg. Peak

5. Electric Fast Transient

Purpose: To evaluate how electrical and electronic equipment operates under interference

Standard:

EN 61000-4-4 / IEC 61000-4-4

Specification:

Test Voltage : ± 6kV

Repetition Frequency : 5 KHz and 100KHz

Power Line : Power Line CDN

Signal / Telecom Line : Capacitive Coupling Clamp

Method : Injection

6. Conducted Suscepibility:

Purpose: To evaluate device response to low- mid frequency noise on the conductors.

Standard:

EN 55011 / CISPR 11, EN 55014-1 / CISPR 14-1; EN 55015 / CISPR 15; EN 55016 / CISPR 16; EN 55032 / CISPR 32

Specification:

Frequency Range : 150KHz to 230 MHz

Field Strength : 1Vrms to 30Vrms

Modulation Frequency : 1 Hz to 50KHz (Variable)

Modulation : AM, CW & PM

7. Power Frequency Magnetic Field:

Purpose: To simulate the impact of magnetic field (such as those near larger transformers) formed by AC and DC power lines on the equipment undergoing testing

Standard:

EN 61000-4-8 / IEC 61000-4-8

Specification:

Field Strength : 1 A/m to 1000 A/m

Frequency : 50 Hz & 60Hz

Induction Coil : AM, CW & PM

8. Voltage Dips & Interruption:

Purpose: To stimulate the affected of voltage dips, short interruptions or voltage variations of power supply on electronic or electrical products.

Standard:

EN 61000-4-11 / IEC 61000-4-11

Specification:

Input Voltage : AC single phase 265Vac 16A,

AC Three Phase 415Vac 32A

Voltage Dips : 0% to 100%

Phase Angle : 0° to 360°

Test Duration : 0.05msec to 9999sec

Dips Interval : 0.01sec

9. Harmonics Flicker:

Purpose: To stimulate the affected of flicker and harmonics on electrical product which are electrical disturbances that interfere with power supplies.

Standard:

EN 61000-3-2 / IEC 61000-3-2

EN 61000-3-3 / IEC 61000-3-3

Specification:

Input Voltage : Ac Single Phase 300Vac, 16A

10. Anechoic Chamber:

10 meter Semi Anechoic chamber considered till 40GHz along with Control Room, Amplifier room and one Shielded room.

Accessories including ground reference planes, Test Tables, Test jigs, RF cables and accessories, Software and Firmware

11. Conducted Susceptibility Tests:

Test performance of the equipment in the presence of simulated noise. Objective is to ascertain that EUT shall perform normally under the presence of extraneous noise of certain severity.

Standard:

EN 55011 / CISPR 11, EN 55014-1 / CISPR 14-1; EN 55015 / CISPR 15; EN 55016 / CISPR 16; EN 55032 / CISPR 32

12. Electrical Fast Transients / Burst:

Establishing a common and reproduceable basis for evaluating performance of electronic instrumentation when subjected to repetitive fast transients like those generated by switching of inductive loads, relay contact bouncing or switching of H/V switchgear

Standard:

EN 61000-4-4 / IEC 61000-4-4

Rise Time: 5 n sec.

Duration: 50 n sec.

13. Electrostatic Discharge(ESD):

Used to test the effect of Discharge of Static Electricity when a charged operator touches an equipment

Standard:

EN 61000-4-2 / IEC 61000-4-2

14. Radiated Susceptibility:

To test immunity of equipment against EM fields generated by radio-transmitters like walkie-talkies,radio/TV transmitters as well as industrial unintentional sources

Standard:

IEC 61000-4-3

15. Test Severity Levels:

| S.no | Level | Field Strength(V/m) |

|---|---|---|

| 1. | 1 | 1 |

| 2. | 2 | 3 |

| 3. | 3 | 10 |

| 4. | x | Subject to agreement |

Frequency Range: 80 MHz to 1000MHz

Modulation: 80 % AM @ 1kHz

16. Magnetic Field Immunity Tests:

Power frequency magnetic field (IEC 61000-4-8)

8/20us Pulse magnetic field (IEC 61000-4-9)

1 MHz Damped Oscillatory Magnetic Field (IEC 61000-4-10)

17. Voltage Dips & Interrupts Immunity:

Voltage dips and short interruptions are events that occur due to faults in a power network by sudden changes of large loads. Voltage variations occur by continuously varying loads connected to the power network

Simulates voltage variations, and interruptions caused by short circuits or rapid changes in power. This may cause a sudden and extreme increase in current and a reduction in voltage.

Standards:

EN 61000-4-11 / IEC 61000-4-11

18. Voltage Dips & Interrupts:

Simulates brownouts and blackouts on equipment operation

Standards:

IEC 1000-4-11

19. Flicker Emission:

This test measures voltage fluctuations induced by a device which draws a fluctuating current

Standards:

EN 61000-3-2 / IEC 61000-3-2

EN 61000-3-3 / IEC 61000-3-3

20. Walking Chamber:

Test Perform: To carry out steady state as well as climatic temperature rise test

Standard:

IS 13252/IEC 60695

IS 616/IEC 60065

IEC 61010 & USER SPECIFICATION

Specification:

Inner Space : 2M x 2M x 2M

Temperature : 0 to 100°C

Humidity : 10% to 95%

Control System : Profile controller

Air Circulation : Inner Air circulation

Ramp Rate : 1°C/min

21. Humidity Chamber:

Test Perform: To carry out steady state as well as climatic temperature test

Standard:

IEC 60068-2-1 & IEC 60068-2-2

IS 13252/IEC 60695; IS 616/IEC 60065

IEC 61010 & USER SPECIFICATION

Specification:

Inner Space : 1M x 1M x 1M

Temperature : -65°C to 180°C

Humidity : 10% to 98%

Control System : Profile controller

Air Circulation : Inner Air circulation

Ramp Rate : 3°C/min

22. Dry Heat Chamber:

Test Perform: To carry out steady state as well as cyclic temperature test

Standard:

IEC 60068-2-2

IS 13252/IEC 60695; IS 616/IEC 60065

IEC 61010 & AS PER CUSTOMER REQUIREMENT

Specification:

Inner Space : 0.8M x 1M x 0.6M

Temperature : amb to 300°C

Control System : Single Profile

controller, PLC

Air Circulation : Inner Air circulation

Ramp Rate : 3°C/min

23. Thermal Cyclic:

Test Perform: To carry out steady state as well as cyclic temperature test

Standard:

IEC 60068-2-14 &

AS PER CUSTOMER REQUIREMENT

Specification:

Inner Space : 1M x 1M x 1M

Temperature : -50°C to 180°C

Control System : Profile controller

Air Circulation : Inner Air circulation

Ramp Rate : 10°C/min

24. Thermal Shock:

Test Perform: To carry out rapid change of temperature test

Standard:

IEC 60068-2-14 &

AS PER CUSTOMER REQUIREMENT

Specification:

Inner Space : 0.6M x 0.6M x 0.6M

Temperature : -70°C to 200°C

Control System : Profile controller

Air Circulation : Inner Air circulation

Transfer Time : > 10 sec

25. Vibration Humidity Chamber:

Test Perform: To carry out climatic temperature test combined with vibration

Standard:

IEC 60068-2-86 &

AS PER CUSTOMER REQUIREMENT

Specification:

Inner Space : 2M x 1.5M x 1M

Temperature : amb to 100°C

Humidity : 10% to 100% Rh

Control System : Profile controller

Air Circulation : Inner Air circulation

Ramp Rate : 1°C/min

Temperature : -70°C to 200°C

Control System : Profile controller

Air Circulation : Inner Air circulation

Transfer Time : > 10 sec