View Full equipment list

| S. no | List of Equipments |

|---|---|

| 1 | Temperature Recorder |

| 2 | Sound Level Meter |

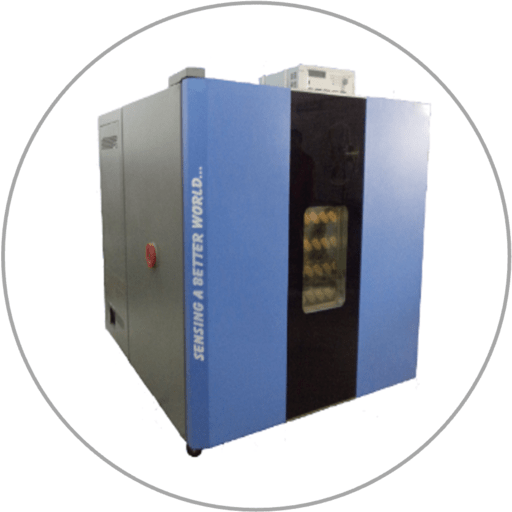

| 3 | Dry Heat Chamber |

| 4 | IPXX Set Up ( this salt spray test chamber is a part of this set up) |

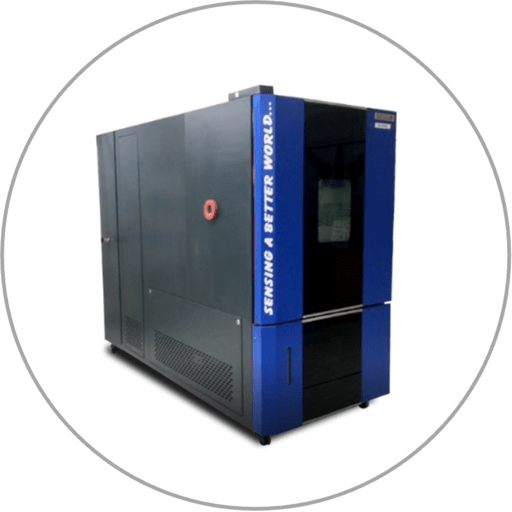

| 5 | Thermal Shock Chamber |

| 6 | Humidity Chamber 1*1*1m |

| 7 | Humidity Chamber Walk In |

| 8 | Ball Impact Test Apparatus |

| 9 | Digital Power Meter |

| 10 | AC Power Supply |

| 11 | HV Tester |

| 12 | Digital Multimeter |

| 13 | Leakage Current Tester |

| 14 | Slip Gauge -Grade II |

| 15 | Weighing Machine upto 200 kg |

| 16 | Integrated Spear for Luminaire' as a part of 'Luminaire Set Up' |

| 17 | Draught Proof Chamber with Fixtures for Luminaire' as a part of 'Luminaire Set Up' |

| 18 | Endurance Set Up for Luminaire' as a part of 'Luminaire Set Up |

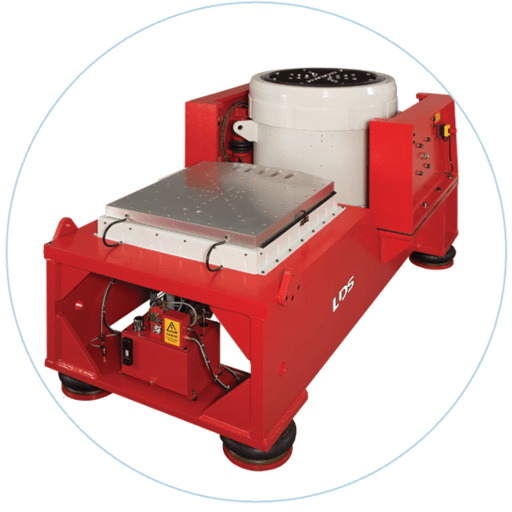

| 19 | Shock and Vibration Test Equipment |

| 20 | Thermocouples, Digital Loads and DC Power Supply |

| 21 | Test Finger |

| 22 | Sharp Edge Tester |

| 23 | Lux Meter |

| 24 | Stop Watch |

| 25 | Isolation Transformer |

| 26 | Dimmer |

| 27 | Light Loop Scale |

| 28 | Angular Meter |

| 29 | Torque Gauge |

| 30 | Push Pull Gauge |

| 31 | Measuring Scale |

| 32 | Beakers |

| 33 | Hardwood Plane of 40 mm |

| 34 | Inclined Plain |

| 35 | Hardwood Plane of 10 mm |

| 36 | Vernier Caliper |

| 37 | Weighing Machine upto 1 kg |

| 38 | Test Bench |

| 39 | Dead Weight |

| 40 | Pressure Gauge |

| 41 | Altitude Chambers |

| 42 | 1 cubic metre High Ramp Chamber 10deg c/ min |

| 43 | Glow Wire Equipment |

| 44 | Tracking Index |

| 45 | Needle Flame |

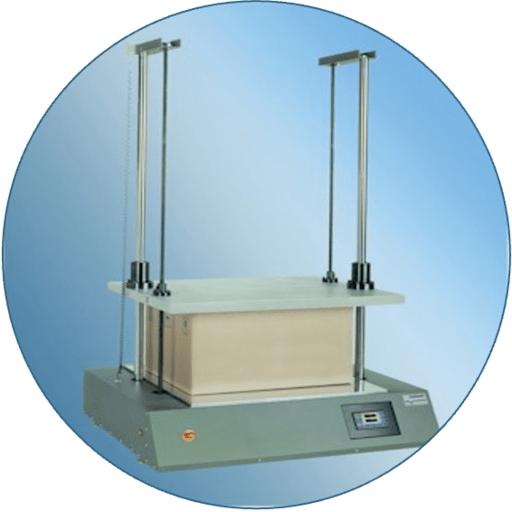

| 46 | Box Compression Tester |

| 47 | Earth bond tester and Ball Pressure Apparatus |

| 48 | PH meter along with Calibration Solutions |

| 49 | Table Top Hygrometer |

| 50 | Clamp Meter |

| 51 | Thermocouple Welding Sation |

| 52 | Digital Barometer |

| 53 | Additional Test Benches |

| 54 | Accessories like Hand drill machine, Tool Box, Pnematic hose Pipe, HV insulation mat, Rain Gauge |

S A F E T Y

1. Ground Bond Test :

- Perform: This test is performed by measuring the resistance between the third pin (ground) and outside metal body of the product under test.

- Purpose: This test is essential so that the product does not cause an electric shock resulting from insulation failure.

Standard Covers:

IEC 60950, IEC 60335, IEC 60065, IEC 62368,

IEC 61010, IEC 60598.

Equipment Specification: Current : 0 to 66 Aac;

Voltage : 0 to 6 Vac;

Resistance : 0.001 to 0.600Ω

2. Leakage Current Test (Line Leakage Test):

- Perform: This test is to measure the undesirable leakage current that flows through or across the surface of the insulation or the dielectric of a capacitor.

- Purpose: To check insulation performance.

Standard Covers:

IEC 60950, IEC 62368, IEC 61010, IEC 60598, 60601, 60990, UL2231 & UL1492

Equipment Specification:

(AC+DC mode): 50µA to 50mA;

(DC mode):50µA to 50mA;

(AC peak mode): 500µA to75mA

3. High Voltage Test:

- Perform: High Voltage testing is usually performed to qualify the device to operate safely during rated electrical conditions, a way to check the effectiveness of its insulation.

- Purpose: To qualify the device to operate safely during rated electrical conditions, a way to check the effectiveness of its insulation.

Standard Covers:

IEC 60950, IEC 60335, IEC 60065, IEC 62368,IEC 61010, IEC 60598.

Equipment Specification:

Ac: 0.050kV to 5kV;

Dc: 0.050kV to 7.2kV;

IR: -25V to -1000V;

IR: +50V to 7200V

4. Comparative Tracking Index Test:

- Perform: Comparative Tracking Index (CTI) is the maximum voltage, measured in volts at which a material withstands 50 drops of contaminated water without tracking.

- Purpose: Used to measure the electrical breakdown (tracking) properties of an insulating material.

Standard Covers:

IEC 60950, IEC 60065, IEC 62368, IEC 61010, IEC 60598.

Equipment Specification:

Drops : 50 Count,

Voltage: up to 600 V

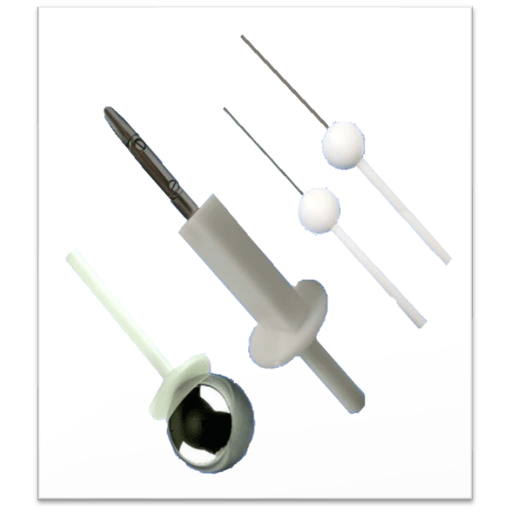

5. Protection Against Electric Shock Test:

- Perform: This test is performed by checking the accessible and removable parts of equipment using probes by applying voltage.

- Purpose: To ensure that hazardous-live-parts shall not be accessible and accessible conductive parts shall not be hazardous.

Standard:

IEC 60950, IEC 60065, IEC 62368, IEC 61010, IEC 60598.

Specification:

Voltage: 40 to 60V

6. Durability Test:

- Perform: This test is perform by rubbing the marking with piece of cloth soaked with water and n Hexane

- Purpose: To ensure the durability of the marking label.

Standard:

IEC 60950, IEC 60065, IEC 62368, IEC 61010, IEC 60598.

Specification:

Aromatic content 0.1% by volume;

Kauri butanol value of 29;

Boiling point 65°C;

Dry point 69°C;

Specified mass of 0.7kg/l

7. PH Test:

- Perform: Place the electrode tip and the temperature probe approximately 4 cm(11/2”) into the sample to be tested.

- Purpose: To ensure the PH, conductivity, Resistivity & TDS of Water or Solution.

Standard:

IEC 60950, IEC 62368, IEC 61010, IEC 60598, 60601, 60990, UL2231 & UL1492

Specification:

PH: (-2) to 20 pH;

Conductivity: 0 to 1000mS/cm;

Resistivity: 1.0 to 100.0MΩ.cm;

8. Input Measurement Test:

- Perform: This test is perform by measuring the input current, power and voltage of equipment using power meter at maximum load condition.

- Purpose: To measure the input consumptions when EUT is operated at is maximum normal load.

Standard:

IEC 60950, IEC 62368, IEC 61010, IEC 60598, 60601, 60990, UL2231 & UL1492

Specification: AC: 30A/15A, 3kVA;

DC: 0 to 438dc, 60A/30A, 6kW;

Hz : 1Hz to 5KHz

9. Heating Test:

- Perform: This test is perform by measuring the temperature the of critical part of equipment by thermocouple method.

- Purpose: Heating tests determines temperature rise and their thermal behaviourof various critical points identified in EUT.

Standard:

IEC 60950, IEC 60065, IEC 62368, IEC 61010, IEC 60598.

Specification:

K Type: (-270°C) to 1370°C.

10. Capacitor Discharge Test:

- Perform: This test is perform by measuring the voltage of bleeder resistor after disconnecting from the mains

- Purpose: Insures that adequately sized bleeder resistors or equivalent are included in the

Standard:

IEC 60950, IEC 60065, IEC 62368, IEC 61010, IEC 60598 & IEC 60335

11. Needle Flame Test:

- Perform: The test flame is positioned so that the tip of the flame is in contact with the surface of the test specimen. The test flame is removed after the specified time.

- Purpose: For the assessment of fire hazard caused by small flames.

Standard:

IEC 60950, IEC 60065, IEC 62368, IEC 61010,IEC 60598.

Specification:

100°C to 700°C within 23.5 sec ± 1 sec

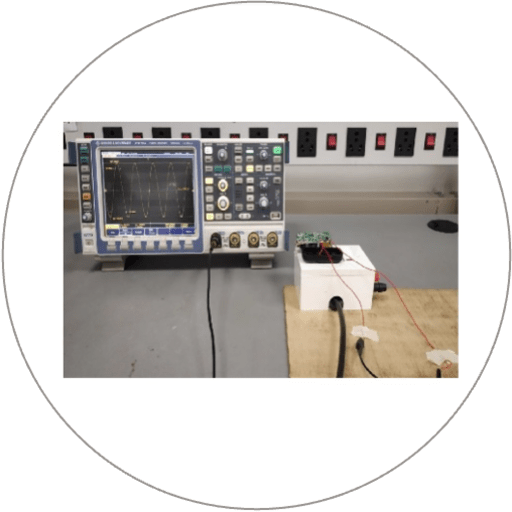

12. Working Voltage Test:

- Perform: This test is perform by measuring the RMS and Peak working voltage of equipment using Oscilloscope and 1000x Probe.

- Purpose: To measure the maximum RMS and Peak working voltages across the Insulations.

Standard:

IEC 60950, IEC 60065, IEC 62368, IEC 61010, IEC 60598.

13. Glow Wire Test:

- Perform: The tip of the glow-wire brought slowly into contact with the test specimen for 30 sec with force exerting of 1N

- Purpose: To simulate heating effects that may arise in malfunctioning electricalequipment caused by an overloaded connection or component that is overheating.

Standard:

IEC 60695-2-10, VDE 0471

Specification:

960°C ± 15°C, 120A to 150A

14. Insulation Resistance:

- Perform: This test is perform by applying the voltage of 500Vdc or 1000Vdc as per standard between the measuring terminals.

- Purpose: This test is to measure the total resistance of a product’s insulation by applying a voltage of 500 V – 1000 V for low voltage systems.

Standard:

IEC 60065, IEC 62368, IEC 61010, IEC 60598.

Specification:

Ac: 0.050kV to 5kV;

Dc: 0.050kV to 7.2kV;

IR: -25V to -1000V;

IR: +50V to 7200V

I N G R E S S

P R O T E C T I O N

Ingress protection ratings or IP ratings, refer to the level of protection offered by an electrical enclosure, against solids and liquids.

In an environment where dust or water could damage electronic components, a sealed enclosure is used to prevent such ingress and safe house the electronics.

They are commonly used for applications which may be exposed to the elements, as well as dust or moisture. Typical industries include marine, offshore oil and gas platforms, security, lighting, leisure, food processing and more.

1. Solid Particle Protection:

- Purpose: To verify the degree of protection that the enclosure provides against access to hazardous parts (e.g., electrical conductors, moving parts) and the ingress of solid foreign objects

Standard:

IS 60529, IEC 60529, ISO 20653, ANSI/IEC 60529, BS EN 60529 & DIN 40050-9

Specification:

IP1X : Test Probe A

Metal:- 50mm sphere, Insulated Handle:- Length : 100mm, Dia.: 10mm; Insulated Guard:- Thickness: 4mm; Dia.: 45mm

IP2X : Test Probe B

Metal Part:- Length: 80mm, Thickness: 12mm, Tip Angle: 37°, 14°;

Insulated Handle: Length : 100mm, Dia.: 50mm, Thickness: 20mm;

Insulated Guard: Thickness: 5mm; Dia.: 75mm

IP3X : Test Probe C

Metal Part:- Length: 100mm, Dia.: 2.5mm; Insulated Sphere: Dia. : 35mm; Insulated Handle: Length: 100mm; Dia.: 10mm

IP3X : Test Probe D

Metal Part:- Length: 100mm, Dia.: 1 mm; Insulated Sphere: Dia. : 35mm; Insulated Handle: Length: 100mm; Dia.: 10mm

2. Solid Particle Protection:

- Purpose: To verify the degree of protection that the enclosure provides against access to hazardous parts (e.g., electrical conductors, moving parts) and the ingress of Dust & Dust particles.

Standard:

IS 60529, IEC 60529, ISO 20653, ANSI/IEC 60529, BS EN 60529 & DIN 40050-9

Specification:

IP5X & IP6X : Dust Chamber

- Chamber Size: 1M x 1M x 1M

- Volume: 1000 Litters

- Free-flow dust circulation centrifugal blower.

- Uniform floating dust simulation across the test space.

- Hopper re-vibration for free fall of settled dust.

- Blower speed regulation to ensure metered uniform dust floating inside the test space.

- Oil-free vacuum pump to simulate negative pressure for IP6X test.

- Volumetric air-flow meter/counter for IP6X test.

- Full view window with illumination.

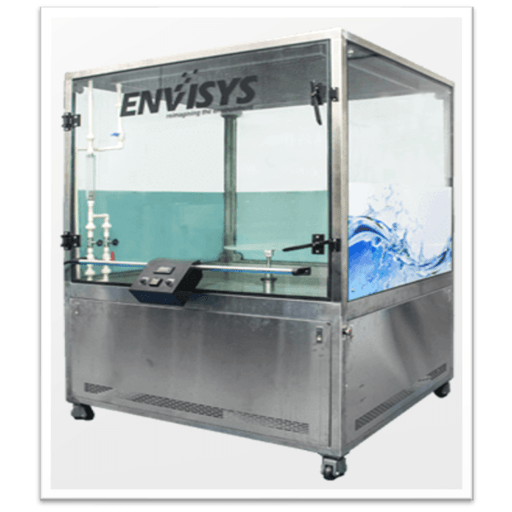

3. Liquid Ingress Protection:

- Purpose: Dripping water (vertically falling drops) shall have no unsafe effect on the specimen when mounted in an upright position onto a turntable and rotated at 1 RPM.

Standard:

IS 60529, IEC 60529, ISO 20653, ANSI/IEC 60529, BS EN 60529 & DIN 40050-9

Specification:

IPX1 & IPX2 : Rain Chamber

- Chamber Size: 1M x 1M x 1M

- Volume: 1000 Litters

- Free-flow water circulation, highly reliable water circulation pump and pipeline.

- Uniform water flow

- Vibration-free rotating table with variable speed control

- High dimensional accurate nozzles made in single operation CNC

- Full-view glass door with wiper

- Touch screen based complete user-programmable console capable of controlling and monitoring rain test parameters viz., pressure, flow-rate, set duration etc.

4. Liquid Ingress Protection:

- Purpose: Water splashing against the enclosure from any angle up to 60° from the vertical / any direction shall have no harmful effect

Standard:

IS 60529, IEC 60529, ISO 20653, ANSI/IEC 60529, BS EN 60529 & DIN 40050-9

Specification:

IPX3 & IPX4 : Rain Chamber

- Size : 1M x 1M x 1M

- Free-flow water circulation, highly reliable water circulation pump and pipeline.

- Uniform water flow

- Vibration-free rotating table with variable speed control

- High dimensional accurate nozzles made in single operation CNC

- Touch screen based complete user-programmable console capable of controlling and monitoring water flow set duration etc.

5. Liquid Ingress Protection

- Purpose: Water projected in powerful jets (6.3 mm (0.25 in)) / (12.5 mm (0.49 in)) against the enclosure from any direction shall have no harmful effects.

Standard:

IS 60529, IEC 60529, ISO 20653, ANSI/IEC 60529, BS EN 60529 & DIN 40050-9

Specification:

IP5X & IP6X : Rain Chamber

- Free-flow water circulation, highly reliable water circulation pump and pipeline.

- Uniform water flow

- Vibration-free rotating table with variable speed control

- High dimensional accurate nozzles made in single operation CNC

- Touch screen based complete user-programmable console capable of controlling and monitoring water flow set duration etc.

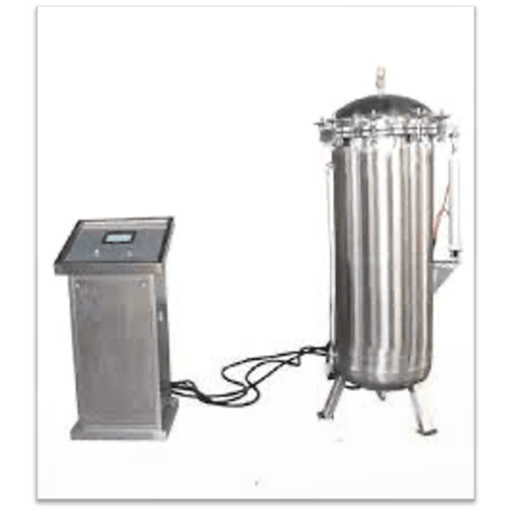

6. Liquid Ingress Protection:

- Purpose: The equipment is suitable for continuous immersion in water under conditions which shall be specified by the manufacturer. However, with certain types of equipment, it can mean that water can enter but only in such a manner that it produces no harmful effects.

Standard:

IS 60529, IEC 60529, ISO 20653, ANSI/IEC 60529, BS EN 60529 & DIN 40050-9

Specification:

IP7X & IP8X : Immersion Tank

- Size : 2M x 1M x 1M

- High quality corrosive resistance material for construction

- Immersion tank is as per standards requirement

M E C H A N I C A L

Mechanical testing covers a wide range of tests.

Vibration is a mechanical phenomenon whereby oscillations occur about an equilibrium point. The most common types of vibration testing services conducted by vibration test labs are sinusoidal and random.

Mechanical shock is a sudden pulse exerted onto a system. A shock test may run multiple pulses, but each is independent of the previous.

A compression test is any test in which a material experiences opposing forces that push inward upon the specimen from opposite sides or is otherwise compressed, “squashed”, crushed, or flattened.

The impact test is a method for evaluating the toughness, impact strength and notch sensitivity of equipment.

1. Vibration

- Test Perform:

- Sine, Half sine, Random, Shock, SOR, ROR in all 3 axis.

- Resonance tracking for the entire frequency range.

- Various custom profiles can be programmed.

Standard:

- IEC EN 60601-1-11, IEC 60086-4

- IEC EN 60068-2-6 & 60068-2-64

- ISO 16750-3

- IEC EN 60870-2-2

- IS 16046 & ISTA

Specification:

Capacity : 3500 Kgf

Max.g : 120 g

Head Expander : 1000 mm²

Slip Table : 900 mm²

Displacement : 76.2 mm pk-pk

Axis : 3 axis

Frequency : DC to 3000 Hz

2. Shock:

- Test Perform:

- Shock in all 3 axis.

- Resonance tracking for the entire frequency range.

- Various custom profiles can be programmed.

Standard:

- IEC EN 60601-1-11, IEC 60086-4

- IEC EN 60068-2-6, 60068-2-27 & 60068-2-64

- ISO 16750-3

- IEC EN 60870-2-2

- ISTA

Specification:

Capacity : 3500 Kgf

Max.g : 120 g

Head Expander : 1000 mm²

Slip Table : 900 mm²

Displacement : 76.2 mm pk-pk

Axis : 3 axis

Frequency : DC to 3000 Hz

3. Chamber

- Test Perform:

- Damp Heat, Damp Hea Cyclic, Thermal Cyclic

- Dry Heat

- Combined Environmental & Vibration Testing

Standard:

- IEC 60601-11, IEC 60068-2-38, 60068-2-78, 60068-2-30

- MIL STD 810, QM 333, SAE J 1455, AIS 076, IS 366

- ISO 9000- 5 & 6, IS 16102, IS 16103, IS 366, IS 15885

- JASO D001-94, ESTI EN 300 019-2-6, IEC 61439-1&2

Specification:

Capacity : 3500 Kgf

Max.g : 120 g

Head Expander : 1000 mm²

Frequency : DC to 3000 Hz

Chamber Size : 1.5M x 1.5M x 1M

Temp. Range : -65°C to 180°C

Humidity : 10% to 98%

Ramp Rate : 5°C/min

4. Squeeer:

- Test Perform:

- Compression Testing

- Crush Test

Standard:

- ISTA, ASTM D642, D4169, D4577; TAPPI T804

- Federal 101, NMFC Item, 180, DOT Rule 181,

- UN Orange Book, ISO 2872 and ISO 874.

- IEC 60065, IEC 62368, IEC 61010, IEC 60598.

Specification:

Max Force : 5000 lbs (22.2kN)

Platen Size : 76 cm x 76 cm

Max Opening : 122 cm

Modes : Constant Rate Mode &

Constant Load mode

5. Impact:

- Test Perform:

- Vertical Impact Test

- Horizontal Impact Test

Standard:

- IEC 60065

- IEC 62368

- IEC 61010

- IEC 60598

Specification:

Weight : 500 gm

Dimeter : 50 mm

Material : Steel

E N V I R O N M E N T A L

Mechanical testing covers a wide range of tests.

Vibration is a mechanical phenomenon whereby oscillations occur about an equilibrium point. The most common types of vibration testing services conducted by vibration test labs are sinusoidal and random.

Mechanical shock is a sudden pulse exerted onto a system. A shock test may run multiple pulses, but each is independent of the previous.

A compression test is any test in which a material experiences opposing forces that push inward upon the specimen from opposite sides or is otherwise compressed, “squashed”, crushed, or flattened.

The impact test is a method for evaluating the toughness, impact strength and notch sensitivity of equipment.

1. WalkIN Chamber:

- Test Perform:

To carry out steady state as well as climatic temperature rise test

Standard:

IEC 60068-2-78, IEC 60950, IEC 60335, IEC 60065, IEC 62368, IEC 61010, IEC 60598, MIL standard, RTCA DO-160

Specification:

Inner Space : 2M x 2M x 2M

Temperature : 0 to 100°C

Humidity : 10% to 95%

Control System : Profile controller

Air Circulation : Inner Air circulation

2. Dry-Heat Chamber:

- Test Perform:

To carry out steady state as well as cyclic temperature test

Standard:

IEC 60068-2-2, IEC 60950, IEC 60335, IEC 60065, IEC 62368, IEC 61010, IEC 60598, IEC 60068-2-30, MIL standard, RTCA DO-160

Specification:

Inner Space : 0.8M x 1M x 0.6M

Temperature : amb to 300°C

Control System : Single Profile

controller, PLC

Air Circulation : Inner Air circulation

3. Thermal Chamber:

- Test Perform:

To carry out steady state as well as temperature cyclic test

Standard:

IEC 60068-2-14, IEC 60068-2-38, IEC 60950, IEC 60335, IEC 60065, IEC 62368, IEC 61010, IEC 60598, IEC 60068-2-30, MIL standard, RTCA DO-160

Specification:

Inner Space : 1M x 1M x 1M

Temperature : -50°C to 300°C

Control System : Profile controller

Air Circulation : Inner Air circulation

4. Humidity Chamber:

- Test Perform:

To carry out steady state as well as climatic temperature rise test

Standard:

IEC 60068-2-78, IEC 60950, IEC 60335, IEC 60065, IEC 62368, IEC 61010, IEC 60598, MIL standard, RTCA DO-160

Specification:

Inner Space : 1M x 1M x 1M

Temperature : 0 to 100°C

Humidity : 10% to 100%

Control System : Profile controller

Air Circulation : Inner Air circulation

5. Altitude Chamber:

- Test Perform:

To carry out steady state as well as climatic temperature rise test

Standard:

IEC 60068-2-13, IEC 60068-2-39, MIL standard, RTCA DO-160

Specification:

Inner Space : 1M x 1M x 1M

Temperature : 0 to 100°C

Humidity : 10% to 95%

Control System : Profile controller

Air Circulation : Inner Air circulation

P H O T O M E T R Y

Photometry is the science of the measurement of light, in terms of its perceived brightness to the human eye. It is distinct from radiometry, which is the science of measurement of radiant energy in terms of absolute power.

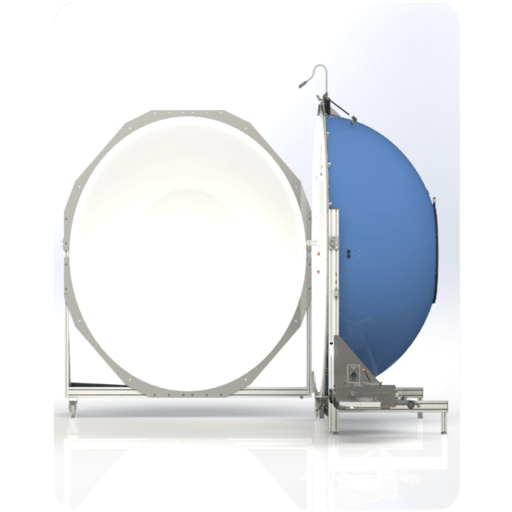

(Integrating sphere) Sphere photometry is used for the determination of total luminous flux output of light sources and measurement of light output ratio (LOR) of luminaries.

Photometric measurement is based on photodetectors, devices (of several types) that produce an electric signal when exposed to light.

Spherical photometers can be used to measure the directional luminous flux produced by lamps, and consist of a large-diameter globe with a lamp mounted at its centre.

1. Integrating Sphere:

An integrating sphere can be used to measure the diffuse reflectance of surfaces, providing an average over all angles of illumination and observation.

Standard:

IS 16106, CIE 177, CIE84, CIE-13.3, IES LM-79-19, Optical-Engineering-49-3-033602, Commission Delegated Regulation(EU) 2019/2015, IESNA LM-63-2 and ANSI-C78.377

2. Endurance Test/ Life Test:

Life Test is that it is conducted under controlled conditions to obtain optimally comparable data on individual lamp life, changes in light output, and other parameters that vary during the life of the lamp.

Standard:

IS 16102 (Part 2), IS 15111(Part 2), IS 2418, IES LM49, IES LM47, IES LM60, IES LM40, IES LM65, IS 10322-1

3. Integrating Sphere:

The draugh-proof chamber applicable under normal operation and is detected lamps temperature air convection under abnormal operation, to prevent the effects of air temperature and thermal radiation from the light source to the sample.

Standard:

IEC60598, IS 10322-1 and GB7000.1-2007

E M I / E M C

Electromagnetic compatibility (EMC) is the ability of electrical equipment and systems to function acceptably in their electromagnetic environment, by limiting the unintentional generation, propagation and reception of electromagnetic energy which may cause unwanted effects such as electromagnetic interference (EMI) or even physical damage in operational equipment.

The goal of EMC is the correct operation of different equipment in a common electromagnetic environment. It is also the name given to the associated branch of electrical engineering.

EMC pursues three main classes of issue. Emission is the generation of electromagnetic energy, whether deliberate or accidental, by some source and its release into the environment.

1. Radiated Emission:

Purpose: To measure the electromagnetic field strength of the emissions that are unintentionally generated by your product.

Standard:

EN 55011 / CISPR 11; EN 55016 / CISPR 16; EN 55032 / CISPR 32;

Specification:

Frequency Range : 30MHz to 1 GHz

Measurement Distance : 10 Meter & 3 Meter

Antenna Polarization : Vertical & Horizontal

Antenna Height : 1 Meter to 4 Meter

Measurement Parameters : Peak, Quasi & Avg. Peak

2. Surge Voltage:

Purpose: To find shorts and insulation weaknesses in coils, windings, electric motors, generators, alternators and transformers.

Standard:

EN 61000-4-5 / IEC 61000-4-5

Specification:

Power Line up to : ± 6kV

Signal Line up to : ± 6kV

Phase angle : 0° to 360°

Power Line : Power Line CDN

Signal / Telecom Line : IO CDN / Telecom CDN

Method : Injection

3. Electrostatic Discharge:

Purpose: To evaluate the durability of electronic devices when electrostatic discharge occurs when a person touches them.

Standard:

EN 61000-4-2 / IEC 61000-4-2

Specification:

ESD Generator Parameter : ± 30kV

Support up to

Discharge Type : Contact & Air

Discharge Networks : 150pF/330Ω; 150 pF/2KΩ

330 pF/2K Ω; 330pF/330Ω

4. Conducted Emission:

Purpose: To measure the portion of electromagnetic energy created by the product that is conducted onto the power supply cord.

Standard:

EN 61000-4-2 / IEC 61000-4-2

Specification:

Frequency Range : 9KHz to 30 MHz

Measurement Method : Voltage & Current Probe

Measurement Facility : Shielded Room

Maximum Current Capacity : up to 200A

Measurement Parameters : Peak, Quasi & Avg. Peak

5. Electric Fast Transient

Purpose: To evaluate how electrical and electronic equipment operates under interference

Standard:

EN 61000-4-4 / IEC 61000-4-4

Specification:

Test Voltage : ± 6kV

Repetition Frequency : 5 KHz and 100KHz

Power Line : Power Line CDN

Signal / Telecom Line : Capacitive Coupling Clamp

Method : Injection

6. Conducted Suscepibility:

Purpose: To evaluate device response to low- mid frequency noise on the conductors.

Standard:

EN 55011 / CISPR 11, EN 55014-1 / CISPR 14-1; EN 55015 / CISPR 15; EN 55016 / CISPR 16; EN 55032 / CISPR 32

Specification:

Frequency Range : 150KHz to 230 MHz

Field Strength : 1Vrms to 30Vrms

Modulation Frequency : 1 Hz to 50KHz (Variable)

Modulation : AM, CW & PM

7. Power Frequency Magnetic Field:

Purpose: To simulate the impact of magnetic field (such as those near larger transformers) formed by AC and DC power lines on the equipment undergoing testing

Standard:

EN 61000-4-8 / IEC 61000-4-8

Specification:

Field Strength : 1 A/m to 1000 A/m

Frequency : 50 Hz & 60Hz

Induction Coil : AM, CW & PM

8. Voltage Dips & Interruption:

Purpose: To stimulate the affected of voltage dips, short interruptions or voltage variations of power supply on electronic or electrical products.

Standard:

EN 61000-4-11 / IEC 61000-4-11

Specification:

Input Voltage : AC single phase 265Vac 16A,

AC Three Phase 415Vac 32A

Voltage Dips : 0% to 100%

Phase Angle : 0° to 360°

Test Duration : 0.05msec to 9999sec

Dips Interval : 0.01sec

9. Harmonics Flicker:

Purpose: To stimulate the affected of flicker and harmonics on electrical product which are electrical disturbances that interfere with power supplies.

Standard:

EN 61000-3-2 / IEC 61000-3-2

EN 61000-3-3 / IEC 61000-3-3

Specification:

Input Voltage : Ac Single Phase 300Vac, 16A